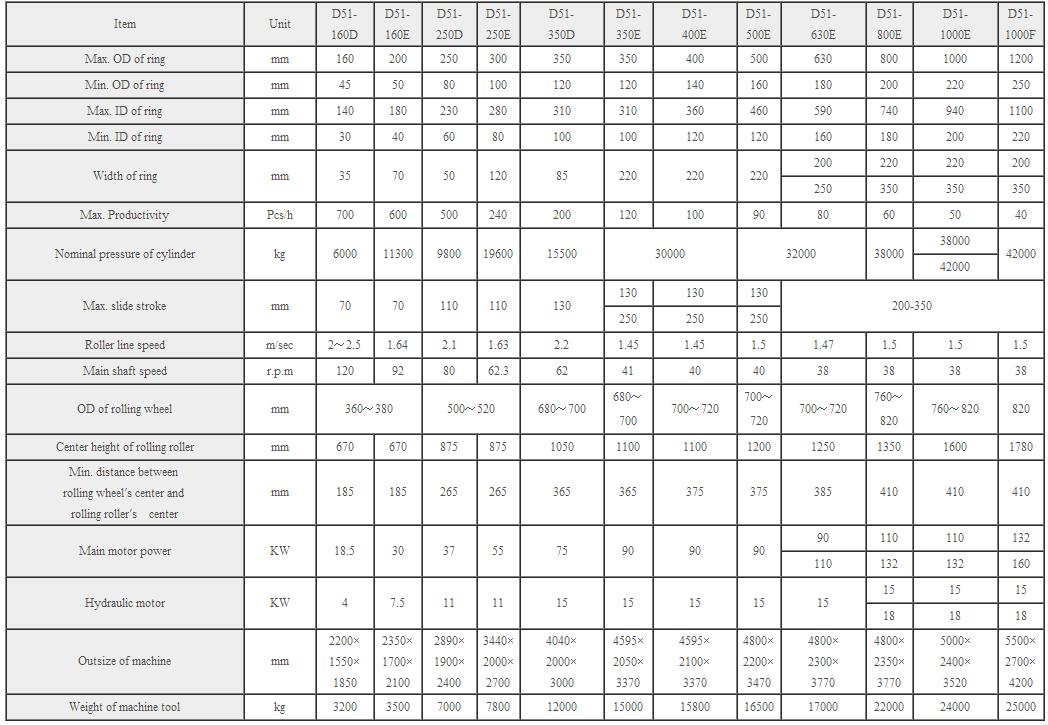

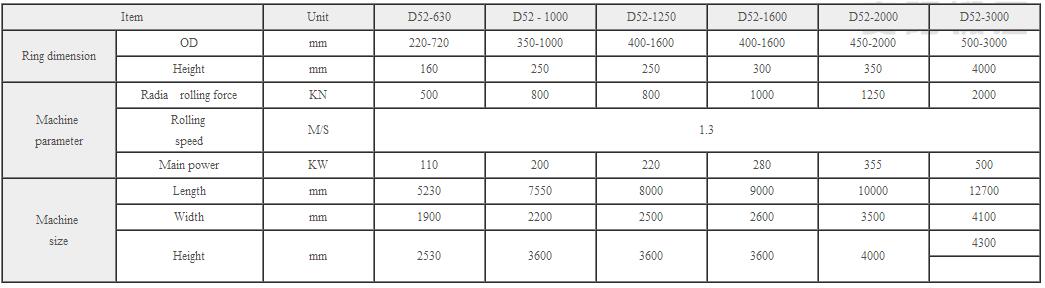

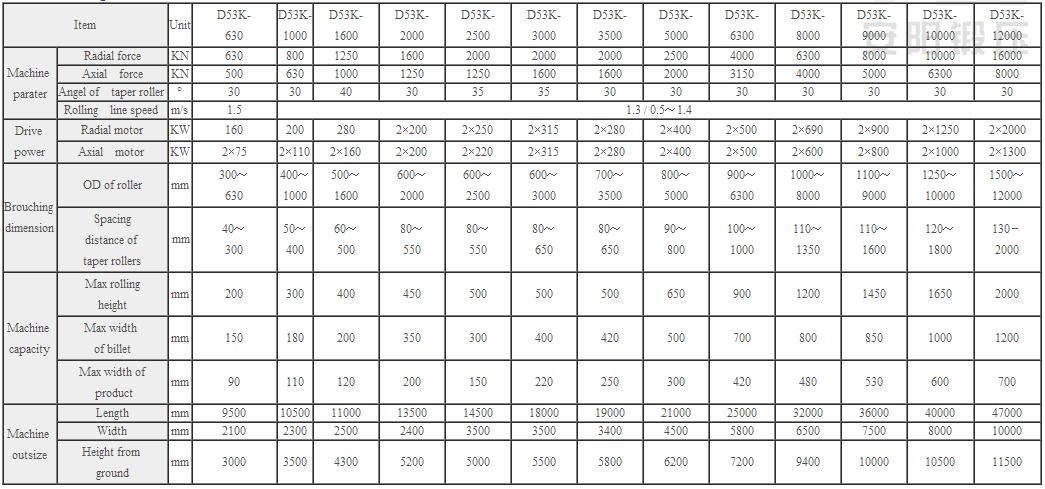

Ring rolling machines / millers are precisely adapted to meet the customer's requirements and rolls both profiled and rectangular rings with a high degree of precision as well as cost-effectively. The machine concept is particularly maintenance and user-friendly. Advantages: Ring rolling machine / millers are divided into the radial rolling and radial-axial rolling type. The radial rolling are divided into vertical type (D51 series, normally produce the ring from 45mm-1200mm) and horizontal type (D52 series, PLC controlled). radial-axial rolling horizontal type (D53K series, CNC controlled can mill the ring from 1000mm - 120000mm). Email: info@chinesehammers.com D51 series (vertical type) Ring Rolling Machine Parameters D52 series (horizontal type) Ring Rolling Machine Parameters D53 series (horizontal type) Ring Rolling Machine Parameters

Ring rolling machines are suitable for producing rings for the following applications: Flanges, Bearings, Gears, Wheels, Sleeves, Rings in the automobile, aerospace, oil & gas industry etc.

1. High material utilization

2. Good quality

3. Good working conditions, high productivity

4. Low production costs