- Home

- About us

- Branch company

- CNC Forging Hammer Branch Company

- Hydraulic Forging Hammer Branch Company

- Pneumatic Forging Hammer Branch Company

- Hydraulic Forging Press Branch Company

- Forging Auxiliary Machine Branch Company

- Hydraulic Riveting Machine Branch Company

- Metal Recycling Machine Branch Company

- CNC Precision Closed Die Forging Company

- Billet cutting machine branch company

- Grinding balls equipment branch company

- Ring rolling machine branch company

- Product

- CNC Hydraulic Die Forging Hammer

- Hydraulic Closed Die Forging Hammer

- Hydraulic Open Die Forging Hammer

- Pneumatic Forging Hammer

- Hydraulic Open Die Forging Press

- Electric Screw Press

- Automatic Roll Forging Machine

- Forging Manipulator

- Forging Charger

- Hydraulic Riveting Machine

- Metal Chips Briquetter

- Hydraulic Baling Press

- Ring rolling machine

- Billet Precision Cutting Machine

- Horizontal Metal Band Sawing Machine

- Skew rolling machine for grinding balls

- Key/wedge driver

- R&D Center

- After Service

- International

- Contact

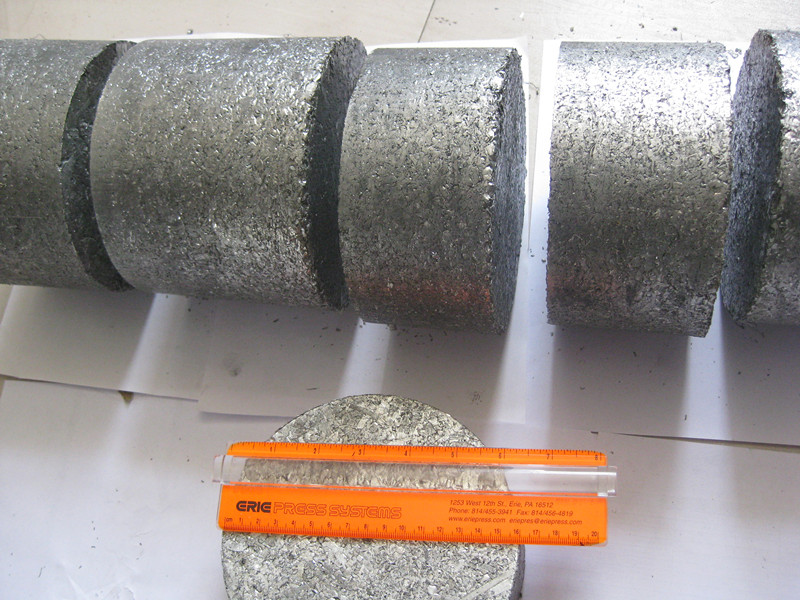

On the condition of not adding additive, the briquetting press can compress all kinds of cast iron, aluminum, copper, brass, mild steel etc metal chips to high density metal blocks. It also allows for the reclamation of valuable coolant, reduces floor space storage requirements, handling and transport costs.

As the customer required, we can supply automatic feeder and conveyor to eased the workforce intensity.

We can supply the electric cooler, which can meet 24 hours production. If you want to learn more, please send requirements to:

info@chinesehammers.com

- Metal scrap briquetting press machine can compact the different kinds of chips like cast iron,aluminum,copper,magnesium,titanium,molybdenum etc metal crap chips into high density blocks without any additive.

- Metal scrap briquetting press machine is the fully hydraulic control equipment,he electric equipment main control part adopts PLC control, the whole working process can realize the automatic operation, reduce the labor intensity and labor.

- The system is provided with a manual work procedures, easy to realize the move forward and backward, the mold open and close action adjustment.

- The device is provided with one time and two times feeding program,easy to press different size of metal chips

- According to customer requirements can increase the automatic feeding, discharging device

- Hydraulic system adopts two-ways cartridge valve, with the good sealing performance, good open and close characteristics, pollution resistant etc advantages.

- Special unloading loop and the liquid electrical switch protection circuit is arranged in the hydraulic system, to make the machine run smoothly, but also improve the service life of hydraulic components.

- The electric control adopts the manual,automatic and two times feeding technology, can conveniently adjust the operation mode and the feeding length, in order to get the material pressing block suppression of different materials and sizes.

- The machine adopts the micro movement hopper on pressing device,solved the not easy to feed and discharge problem,also reduce the abrasion of the guard of discharging.

- The hydraulic cylinder adopts the main pressure cylinder and fast forward cylinder connected to form the composite cylinder, improve the operating speed, reducing the energy consumption of the motor, but also improve the production efficiency.

- The machine adopts PLC control

- The machine pressed metal block has large diameter, high density, resist broken, good surface finish, not easy oxidation etc advantages.

- This machine adopts a fully enclosed structure form, can recycling cutting fluid in the metal chips and prevent oil leaking pollution.

Metal scrap briquetter usage:

Metal scrap briquetting press machine can compact the different kinds of chips like cast iron,aluminum,copper,magnesium,titanium,molybdenum etc metal crap chips into high density blocks without any additive,greatly reduce the casting cost.

Technical parameters of briquetting press:

|

Item |

unit |

Y83A-160 |

Y83-160 |

Y83-230 |

Y83-300 |

Y83A-300 |

Y83-800 |

Y83-1000 |

|

|

Nominal force |

KN |

1600 |

1600 |

2300 |

3000 |

3000 |

8000 |

10000 |

|

|

Briquetting size |

Mm |

Φ90× (60-85) |

Φ90× (60-110) |

Φ110× (70-120) |

Φ120× (70-120) |

Φ120× (70-120) |

Φ180× (165-180) |

Φ220× (200-250) |

|

|

Briquetting density |

Kg/m3 |

≥5200-5400 |

≥5200-5400 |

≥5200-5400 |

≥5200-5400 |

≥5200-5400 |

≥5200-5400 |

≥5200-5400 |

|

|

Working pressure |

Mpa |

23 |

16 |

23 |

21 |

26.5 |

25 |

25 |

|

|

Production rate |

t/h |

0.6-0.9 |

0.6-0.9 |

1.0-1.5 |

1.2-1.8 |

1.2-1.8 |

6-7.5 |

8.5-12 |

|

|

Total power |

Kw |

24.2 |

24.2 |

39.2 |

47.2 |

49 |

185 |

225 |

|

|

Machine weight |

Kg |

4500 |

6000 |

7500 |

8800 |

7500 |

50000 |

60000 |

|

|

Machine outside size |

Mm |

4900×1470 ×1522 |

4100×1086 ×2006 |

4100×1086 ×2006 |

5000×1600 ×2600 |

4000×1400 ×3700 |

8000×6500 ×2500 |

9000×7500 ×2500 |

|