- Home

- About us

- Branch company

- CNC Forging Hammer Branch Company

- Hydraulic Forging Hammer Branch Company

- Pneumatic Forging Hammer Branch Company

- Hydraulic Forging Press Branch Company

- Forging Auxiliary Machine Branch Company

- Hydraulic Riveting Machine Branch Company

- Metal Recycling Machine Branch Company

- CNC Precision Closed Die Forging Company

- Billet cutting machine branch company

- Grinding balls equipment branch company

- Ring rolling machine branch company

- Product

- CNC Hydraulic Die Forging Hammer

- Hydraulic Closed Die Forging Hammer

- Hydraulic Open Die Forging Hammer

- Pneumatic Forging Hammer

- Hydraulic Open Die Forging Press

- Electric Screw Press

- Automatic Roll Forging Machine

- Forging Manipulator

- Forging Charger

- Hydraulic Riveting Machine

- Metal Chips Briquetter

- Hydraulic Baling Press

- Ring rolling machine

- Billet Precision Cutting Machine

- Horizontal Metal Band Sawing Machine

- Skew rolling machine for grinding balls

- Key/wedge driver

- R&D Center

- After Service

- International

- Contact

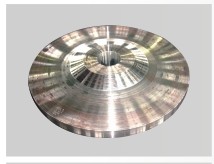

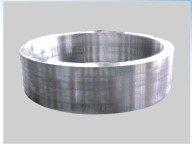

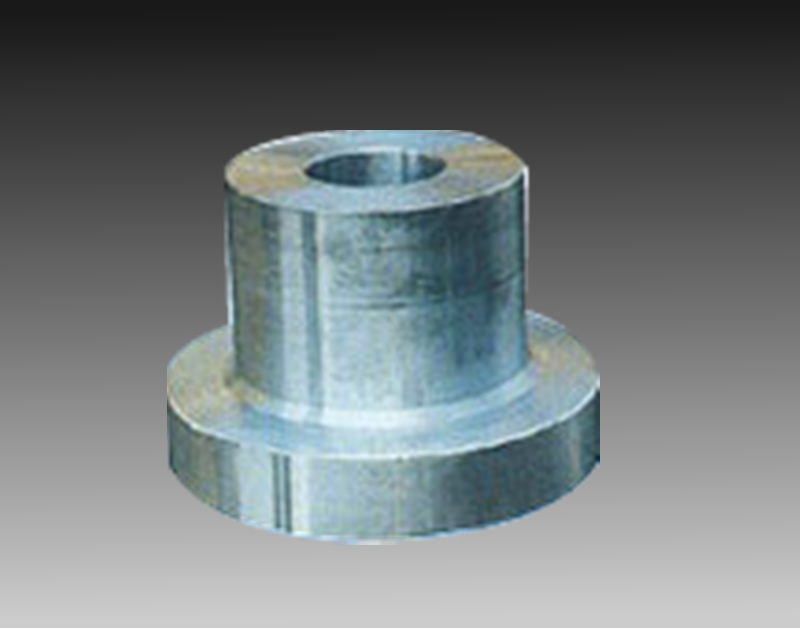

Hydraulic Open Die Forging Hammer includes electro hydraulic open die forging hammer and fully hydaulic open die forging hammer, both are widely accepted in modern open die forging plants, suitable for producing various open die forgings, such as shaft forgings, ring forgings, gear blanks, flanges etc.

Hydraulic open die forging hammer is also called hydraulic free forging hammer.

Buy hydraulic free forging hammer or modification of Hydra-pneumatic free forging hammer, please send email to info@chinesehammers.com

Anyang Forging Press have over 30 years history to produce hydraulic open die foring hammers. The China National standard of hydraulic foring hammer is drafted by us. we not also produce new hydrauli forging hammer, but also can convert the old steam/air forging hammer to be hydraulic forging hammer.

According to the driving medium our hydraulic forging hammer can be divide Hydraulic-Gas foring hammer(C66) and fully Hydraulic forging hammer(C66Y).

As per structure, Hydraulic open die forging hammer includes bridge type open die forging hammer, single-frame hydraulic open die hammer,arch open die hydraulic forging hammer.

[C66 series hydraulic-gas open die forging hammer introduction]

C66 series electro hydraulic forging hammer is a open die forging hammer that adopt hydraulic pressure-nitrogen gas driven. It have bridge type and arch type. Upper chamber of hammer rod piston is nitrogen gas, lower chamber is hydraulic oil. It can realize hitting by controlling the oil of lower chamber. It is used all kinds of open die forging.

[Technical Feature]

1. Energy saving and environmental protection.

2. High frequency hitting, improve production efficiency.

3. Auto lubricating of guide rails.

4. PLC control, after switch on, immediately starting to do forging .

5. Safety and easy operating by hand lever or pedal.

6. High efficiency cooling system for hydraulic oil, which guarantee 8*24 production.

| The main technical parameters of arch type hydraulic open die forging hammer | |||||||

| Item | Unit | C66-35 (1T) |

C66-35 (1T) |

C66-70 (2T) |

C66-120 (3T) |

C66-140 (4T) |

C66-175 (5T) |

| Hit energy | KJ | 35 | 35 | 70 | 120 | 140 | 175 |

| Rated weight of falling parts |

kg | 1300 | 1300 | 2600 | 4200 | 4800 | 6000 |

| Max. stroke | mm | 1000 | 1000 | 1260 | 1450 | 1500 | 1730 |

| Below frequency | min-1 | 50-58 | 65-75 | 65-75 | 50-55 | 50-60 | 45-50 |

| Main motor power | kW | 55 | 45 | 55 | 55 | 55 | 75 |

| Motor/pump number | set | 1 | 2 | 3 | 4 | 5 | 5 |

| Guide space | mm | 460 | 460 | 550 | 630 | 630 | 760 |

| Working area (WxH) | mm | 1800x1250 | 1800x1250 | 2300x1380 | 2700x1470 | 2700x1470 | 3700x2000 |

| Lower die surface height above ground |

mm | 750 | 750 | 750 | 760 | 760 | 880 |

| Machine outside size (LxWxH) |

mm | 3600x 1500x 6000 |

3600x 1500x 6000 |

4500x 1700x 6500 |

5100x 2300x 7500 |

5100x 2300x 7800 |

6300x 2700x 8500 |

| Oil tank outside size (LxWxH) |

mm | 2000x 1500x 1300 |

2000x 1500x 1300 |

2700x 2000x 1600 |

3600x 2000x 1600 |

4500x 2000x 1600 |

4500x 2000x 1600 |

| Item | Unit | C66-210 (6T) |

C66-245 (7T) |

C66-280 (8T) |

C66-350 | C66-420 | C66-490 |

| (10T) | (12T) | (14T) | |||||

| Hit energy | KJ | 210 | 245 | 280 | 350 | 420 | 490 |

| Rated weight of falling parts |

kg | 7000 | 7600 | 8500 | 10500 | 12500 | 14500 |

| Max.stroke | mm | 1850 | 2000 | 2200 | 2400 | 2500 | 2600 |

| Below frequency | min-1 | 45-50 | 46-50 | 45-50 | 44-46 | 42-45 | 42-45 |

| Main motorpower | kW | 75 | 75 | 75 | 75 | 75 | 75 |

| Motor/pump number | set | 6 | 7 | 7 | 10 | 12 | 16 |

| Guide space | mm | 890 | 890 | 980 | 980 | 1050 | 1050 |

| Working area (WxH) | mm | 3700x2150 | 4200x2200 | 4700x2250 | 4800x2350 | 5000x2500 | 5000x2500 |

| Lower die surface height above ground |

mm | 880 | 900 | 900 | 900 | 900 | 900 |

| Machine outside size (LxWxH) |

mm | 6300x 2700x 8800 |

7000x 2700x 9100 |

7500x 2800x 9500 |

7500x 2800x 10000 |

7600x 3000x 12000 |

7600x 3000x 13000 |

| Oil tank outside size (LxWxH) |

mm | 5400x 2000x 1600 |

6300x 2000x 1600 |

6300x 2000x 1600 |

9000x 2000x 1600 |

10800x 2000x 1600 |

2x7200x 2000x 1600 |

| The main technical parameters of bridge type hydraulic free forging hammer | ||||||||

| Item | Unit | C66-175 (5T) |

C66-210 (6T) |

C66-245 (7T) |

C66-280 (8T) |

C66-350 (10T) |

C66-420 (12T) |

C66-490 (14T) |

| Hit energy | KJ | 175 | 210 | 245 | 280 | 350 | 420 | 490 |

| Rated weight of falling parts |

kg | 6000 | 6800 | 7600 | 8500 | 10500 | 12500 | 14500 |

| Max. stroke | mm | 1730 | 1850 | 2000 | 2200 | 2400 | 2500 | 2500 |

| Hit frequency | min-1 | 45-50 | 45-50 | 46-50 | 45-50 | 44-46 | 42-45 | 42-45 |

| Main motor power | kW | 75 | 75 | 75 | 75 | 75 | 75 | 75 |

| Motor/pump number | set | 5 | 6 | 7 | 7 | 10 | 12 | 16 |

| Guide space | mm | 830 | 930 | 930 | 1030 | 1030 | 1050 | 1050 |

| Working area (WxH) | mm | 3700x2000 | 3700x2150 | 4200x2300 | 4200x2460 | 4400x2650 | 4500x2800 | 4500x2900 |

| Lower die surface height above ground |

mm | 880 | 880 | 900 | 900 | 900 | 900 | 900 |

| Machine outside size (LxWxH) |

mm | 6300 x2700 x8500 |

6300 x2700 x8800 |

7000 x2700 x9100 |

7500 x2800 x9500 |

7500 x2800 x10000 |

7600 x3000 x12000 |

7600 x3000 x13000 |

| Oil tank Outside size (LxWxH) |

mm | 4500 x2000 x1600 |

5400 x2000 x1600 |

6300 x2000 x1600 |

6300 x2000 x1600 |

9000 x2000 x1600 |

10800 x2000 x1600 |

2x7200 x2000 x1600 |

| The technical parameters of hydraulic free forging hammer (Single arm) | |||||||

| Model | Unit | C61-30 (1T) |

C61-70 (2T) |

C61-105 (3T |

C61-140 (4T) |

C61-175 (5T) |

|

| Hit energy | Kj | 30 | 70 | 105 | 140 | 175 | |

| Rated weight of falling part | kg | 1300 | 2600 | 4000 | 4800 | 5500 | |

| Max stroke | mm | 1000 | 1260 | 1450 | 1700 | 1800 | |

| Hit frequency | min-1 | 50-58 | 65-75 | 50-58 | 50-60 | 48-55 | |

| Main motor power | kw | 55 | 55×3 | 55×4 | 55×5 | 75×5 | |

| Motor/pump number | set | 1 | 3 | 4 | 5 | 5 | |

| Distance between guides | mm | 480 | 560 | 600 | 600 | 700 | |

| Throat depth× throat height |

mm | 730x1750 | 840x2150 | 960x2340 | 960x2500 | 1250x2200 | |

| Lower die surface height above ground |

mm | 750 | 750 | 750 | 750 | 760 | |

| Outside size | mm |

3800x 1680x 7000 |

4260x 1800x 7200 |

4700x 1900x 7600 |

5440x 1900x 8000 |

5700x 2300x8500 |

|

| Oil tank outside size | mm |

2000x 1500x 1300 |

2700x 2000x 1600 |

3600x 2000x 1600 |

4500x 2000x 1600 |

4500x 2000x 1600 |

|

| Model | Unit | C61-210 (6T) |

C61-280 (8T) |

C61-350 (10T) |

C61-420 (12T) |

||

| Hit energy | KJj | 210 | 105 | 140 | 175 | ||

| Rated weight of falling part | kg | 6300 | 4000 | 4800 | 5500 | ||

| Max stroke | mm | 1900 | 1450 | 1700 | 1800 | ||

| Hit frequency | min-1 | 50-55 | 50-58 | 50-60 | 48-55 | ||

| Main motor power | kw | 75 | 75 | 75 | 75 | ||

| Motor/pump number | set | 6 | 7 | 10 | 12 | ||

| Distance between guides | mm | 800 | 1000 | 1100 | 1100 | ||

| Throat depth× throat height |

mm | 1300x2300 | 1400x2400 | 1450x2500 | 1450x2500 | ||

| Lower die surface height above ground |

mm | 760 | 780 | 850 | 900 | ||

| Outside size | mm |

5850x 2400x 8700 |

6400x 2600x 9200 |

6400x 2600 x9300 |

6400x 2600x 9400 |

||

| Oil tank outside size | mm |

5400x 2000x 1600 |

6300x 2000x 1600 |

9000x 2000x 1600 |

10800x 2000x 1600 |

||

[C66Y fully hydraulic open die forging hammer Introduction]

C66Y series fully hydraulic open die forging hammer is fully hydraulic drive open die forging hammer, there single arm type, arch type and bridge type etc structure type. The system principle is the below chamber of hammer rod piston connect the high pressure oil all the time,realize hit through control the upper and below oil pressure of piston of piston.It’s used for open die forging.

[Technical characteristics]

1. Energy saving and environmental protection.

2. High frequency hitting, improve production efficiency.

3. Auto lubricating of guide rails.

4. PLC control, after switch on, immediately starting to do forging .

5. Safety and easy operating by hand lever or pedal.

6. High efficiency cooling system for hydraulic oil, which guarantee 8*24 non-stop production.

|

Item |

Unit |

C66Y-35 |

C66Y-70 |

C66Y-120 |

C66Y-140 |

C66Y-175 |

C66Y-210 |

C66Y-245 |

C66Y-280 |

C66Y-350 |

|

Rated hit energy |

KJ |

35 |

70 |

120 |

140 |

175 |

210 |

245 |

280 |

350 |

|

Weight of falling parts |

kg |

1300 |

2450 |

3750 |

4400 |

5600 |

6600 |

7500 |

8000 |

10000 |

|

Max.stroke |

mm |

1000 |

1260 |

1450 |

1500 |

1730 |

1800 |

1850 |

1900 |

1950 |

|

Hit frequency |

min-1 |

65-75 |

65-75 |

50-55 |

50-60 |

45-50 |

45-50 |

46-50 |

40-45 |

40-45 |

|

Main motor power |

kw |

55×2 |

55×3 |

55×4 |

55×5 |

55×5 |

55×6 |

55×7 |

55×7 |

55×10 |

|

Guide space |

mm |

460 |

550 |

630 |

630 |

760 |

890 |

890 |

980 |

980 |

|

Operating Spaces |

mm |

1800×1250 |

2300×1380 |

2700×1470 |

2700×1470 |

3700×2000 |

3700×2150 |

3820×2200 |

4700×2250 |

4700×2350 |

|

Lower die suface height |

mm |

750 |

750 |

760 |

760 |

880 |

880 |

900 |

900 |

900 |

|

Outslde size |

mm |

3600× 1500× 6000 |

4500× 1700× 6500 |

5100× 2300× 7500 |

5100× 2300× 7800 |

6300× 2700× 8500 |

6300× 2700× 8800 |

7000× 2700× 9100 |

7500× 2800× 9500 |

7500× 2800× 10000 |

|

|

Unit

|

C61Y-30

|

C61Y-70

|

C61Y-105

|

C61Y-140

|

C61Y-175

|

C61Y-210

|

C61Y-280

|

|

Hit energy

|

kj

|

30

|

70

|

105

|

140

|

175

|

210

|

280

|

|

|

||||||||

|

Falling part weight

|

kg

|

1300

|

2600

|

4000

|

4800

|

5500

|

6300

|

8000

|

|

Max. stroke

|

mm

|

1000

|

1260

|

1450

|

1600

|

1730

|

1850

|

1950

|

|

Hit frequency

|

min-1

|

90-150

|

70-120

|

65-100

|

60-100

|

50-80

|

45-80

|

40-70

|

|

Main motor power

|

kw

|

55

|

55

|

55

|

55

|

55

|

55

|

55

|

|

Motor/pump number

|

set

|

2

|

3

|

4

|

5

|

6

|

7

|

8

|

|

Distance between guides

|

mm

|

480

|

560

|

600

|

600

|

700

|

800

|

1000

|

|

Throat depth*throat height

|

mm

|

730*1750

|

840*2150

|

960*2340

|

960*2500

|

1250*2200

|

1300*2300

|

1400*2400

|

|

Lower die surface height above ground

|

mm

|

750

|

750

|

750

|

750

|

760

|

760

|

780

|

|

Outside size

|

mm

|

3800

*1680

*7200

|

4260

*1800

*7400

|

4700

*1900

*7800

|

5440

*1900

*8300

|

5700

*2300

*8800

|

5850

*2400

*9000

|

6400

*2600

*9500

|