- Home

- About us

- Branch company

- CNC Hydraulic Die Forging Hammer Branch Company

- Electro Hydraulic Forging Hammer Branch Company

- Pneumatic Forging Hammer Branch Company

- Hydraulic Forging Press Branch Company

- Forging Auxiliary Machine Branch Company

- Hydraulic Riveting Machine Branch Company

- Metal Recycling Machine Branch Company

- CNC Precision Closed Die Forging Company

- Billet cutting machine branch company

- Grinding balls equipment branch company

- Ring rolling machine branch company

- Product

- CNC Hydraulic Die Forging Hammer

- Hydraulic Closed Die Forging Hammer

- Hydraulic Open Die Forging Hammer

- Pneumatic Forging Hammer

- Hydraulic Open Die Forging Press

- Forging Manipulator

- Forging Charger

- Hydraulic Riveting Machine

- Metal Chips Briquetter

- Hydraulic Baling Press

- Ring rolling machine

- Billet Precision Cutting Machine

- Horizontal Metal Band Sawing Machine

- Skew rolling machine

- R&D Center

- After Service

- International

- Contact

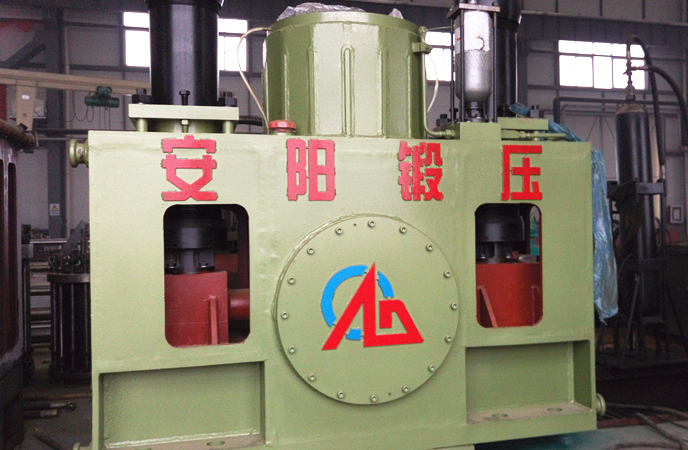

Hydraulic closed die forging hammer includes Electro hydraulic closed die forging hammer and Fully hydraulic closed die forging hammer, both are mainly applied in batches production of all kinds of die forgings,such as automobile forgings,tractor forgings,agricultural equipment forgings, oil and gas industry die forgings, electrical power station die forgings and industrial forgings.

Anyang Forging Press company can convert the old steam hammer, blet drop hammer, Huta Zygmunt hammer into hydraulic forging hammer.

Buy hydraulic die forging hammer or Conversion of Hydra-pneumatic Hammer, please send email to info@chinesehammers.com

[Hydraulic closed die forging hammer Introduction]

C86Y series hydraulic die forging hammer is fully hydraulic driven without gas. Fully hydraulic impression / closed die forging hammer is used for closed / impression die forging.

[Technical characteristics]

- Highly integrated fully hydraulic control system, low carbon, no leakage, more reliable.

- Large flow hitting valve [patent design], sensitive response, high frequency.

- Built-in secondary hydraulic cushion device[ patent design], realized flexible upper limit, no top hitting.

- Tup return fast, die touching time is short, no die block, die life is longer.

- 'X' type guide rail, it can do multi-cavity forging, high forging precision ,long hammer rod life.

- Automatic emergency anti hammer rod breaking cover, anti oil leak timely and safety.

- Multilevel security protection hydraulic device, system stability, high safety.

- Lead control operate valve, reliable control, operating force is small, low labor intensity.

- Traditional hand operate model, the original operator can operate the hammer easily.

|

Item |

Unit |

C86Y-25 |

C86Y-50 |

C86Y-75 |

C86Y-125 |

C86Y-200 |

C86Y-250 |

C86Y-400 |

C86Y-450 |

|

Rated hit energy |

KJ |

25 |

50 |

75 |

125 |

200 |

250 |

400 |

450 |

|

Weight of falling parts |

kg |

1000 |

2000 |

3000 |

5000 |

8000 |

10000 |

16000 |

18000 |

|

Max. stroke |

mm |

1000 |

1200 |

1250 |

1300 |

1350 |

1400 |

1500 |

1500 |

|

Hit frequency |

min-1 |

55-70 |

55-70 |

55-70 |

55-65 |

55-65 |

50-60 |

50-55 |

45-50 |

|

Main motor power |

kw |

75×1 |

75×2 |

75×3 |

75×4 |

75×5 |

75×6 |

75×8 |

75×10 |

|

Min height of close die (without dovetail) |

mm |

220 |

260 |

350 |

400 |

430 |

450 |

500 |

500 |

|

Outside size |

mm |

2400× 1400× 7000 |

3000× 1700× 7500 |

3200× 1800× 8000 |

3700× 2100× 8200 |

4300× 2700× 8800 |

4400× 2700× 9000 |

4500× 2600× 9800 |

4500× 2800× 10000 |

[Hydraulic-gas closed die forging hammer Introduction]

C86 series electro hydraulic forging hammer is a close die forging hammer that adopt hydraulic pressure-nitrogen gas driven. Upper chamber of hammer rod piston is nitrogen gas, lower chamber is hydraulic oil. It can realize hitting by controlling the oil of lower chamber. It is used all kinds of close die forging.

[Technical Feature]

- X type guide rail, it can be multi-cavity forging, high forging precision ,long hammer rod life.

- Compared with steam hammer and air compressor hammer, energy conservation and environment protection.

- Low failure rate, it can realize stop hammer any position.

| Item | Unit | C86-25 (1T) |

C86-50 (2T) |

C86-75 (3T) |

C86-125 (5T) |

| Max. hitting energy | KJ | 25 | 50 | 75 | 125 |

| Weight of falling parts | kg | 1500 | 2500 | 3500 | 6000 |

| Max. stroke | mm | 1000 | 1200 | 1250 | 1300 |

| Hit frequency | min-1 | 55-65 | 55-65 | 50-60 | 45-55 |

| Main motor power | kw | 45 | 45 | 55 | 55 |

| Number of motor | set | 2 | 3 | 3 | 4 |

| Electric-cooler type | type | YLD400 | YLD600 | YLD800 | YLD1200 |

| Electric-cooler capacity | Kcal/h | 40000 | 60000 | 80000 | 120000 |

| Electric-cooler power | kW | 19 | 38 | 38 | 60 |

| Guide space | mm | 540 | 600 | 700 | 740 |

| Min. die height (without dovetail) |

mm | 220 | 260 | 350 | 400 |

| Machine outside size (LxWxH) |

mm | 2400x1400x6000 | 3000x1700x6500 | 3200x1800x7100 | 3700x2100x8600 |

| Oil tank outside size (LxWxH) |

mm | 2000x1500x1300 | 2700x2000x1600 | 2700x2000x1600 | 3600x2000x1600 |

| Item | Unit | C86-150 (6T) |

C86-200 (8T) |

C86-250 (10T) |

C86-400 (16T) |

| Max. hitting energy | KJ | 150 | 200 | 250 | 400 |

| Weight of falling parts | kg | 7000 | 8600 | 10500 | 16300 |

| Max. stroke | mm | 1350 | 1350 | 1400 | 1500 |

| Hit frequency | min-1 | 45-55 | 40-55 | 30-40 | 30-40 |

| Main motor power | kw | 55 | 55 | 55 | 75 |

| Number of motor | set | 5 | 5 | 6 | 8 |

| Electric-cooler type | type | YLD1200 | YLD800x2 | YLD800x2 | YLD1000x2 |

| Electric-cooler capacity | Kcal/h | 120000 | 80000x2 | 80000x2 | 100000x2 |

| Electric-cooler power | kW | 60 | 38x2 | 38x2 | 54x2 |

| Guide space | mm | 800 | 900 | 1000 | 1200 |

| Min. die height (without dovetail) |

mm | 430 | 430 | 450 | 500 |

| Machine outside size (LxWxH) |

mm | 3800x2300x9200 | 4300x2700x11200 | 4400x2700x12000 | 4500x2600x13100 |

| Oil tank outside size (LxWxH) |

mm | 4500x2000x1600 | 4500x2000x1600 | 5400x2000x1600 | 7200x2000x1600 |

[Forging Hammer Power Head Introduction]

Fully hydraulic power head is suitable for conversion of steam hammer, air compressor forging hammer and electro hydraulic forging hammer. It makes old forging hammer to be fully hydraulic forging hammer with all kinds of performance advance, small investment, short cycle, high benefit through conversion. Conversion way:

a. For steam hammer and air compressor forging hammer: using anvil block and hammer frame(with X guide or original type) of original hammer. To match new tup, fully hydraulic power head, hydraulic station and electro control system.

b. For electro hydraulic forging hammer: Using anvil block, hammer frame, tup, hydraulic station and electro control system of original hammer, and to match new fully hydraulic power head.

[Technical Feature]

- Short conversion cycle, small investment, high benefit.

- Low energy consumption.

- High hitting frequency, enough energy.

- Accurate energy control.

- Light operating force, low labor intensity.

|

Item |

Unit |

C86YT-25 |

C86YT-50 |

C86YT-75 |

C86YT-125 |

C86YT-200 |

C86YT-250 |

C86YT-400 |

C86YT- 450 |

|

Rated hit energy |

KJ |

25 |

50 |

70 |

125 |

200 |

250 |

400 |

450 |

|

Weight of falling parts |

kg |

1000 |

2000 |

3000 |

5000 |

8000 |

10000 |

16000 |

18000 |

|

Max.stroke |

mm |

1000 |

1200 |

1250 |

1300 |

1350 |

1400 |

1500 |

1500 |

|

Hit frequency |

min-1 |

55-70 |

55-70 |

55-70 |

55-65 |

55-65 |

50-60 |

50-55 |

45-50 |

|

Main motor power |

kw |

75×1 |

75×2 |

75×3 |

75×4 |

75×5 |

75×6 |

75×8 |

75×10 |

|

Min height of close die (without dovetail) |

mm |

220 |

260 |

350 |

400 |

430 |

450 |

500 |

500 |

if you have any questions about the type or specification of our electro hydraulic die forging hammer or fully hydraulic die forging hammer, please send email to info@chinesehammers.com

.jpg)

Electro hydraulic die forging hammer in Taiwan.jpg)